Services

Damage-Free Surface Cleaning

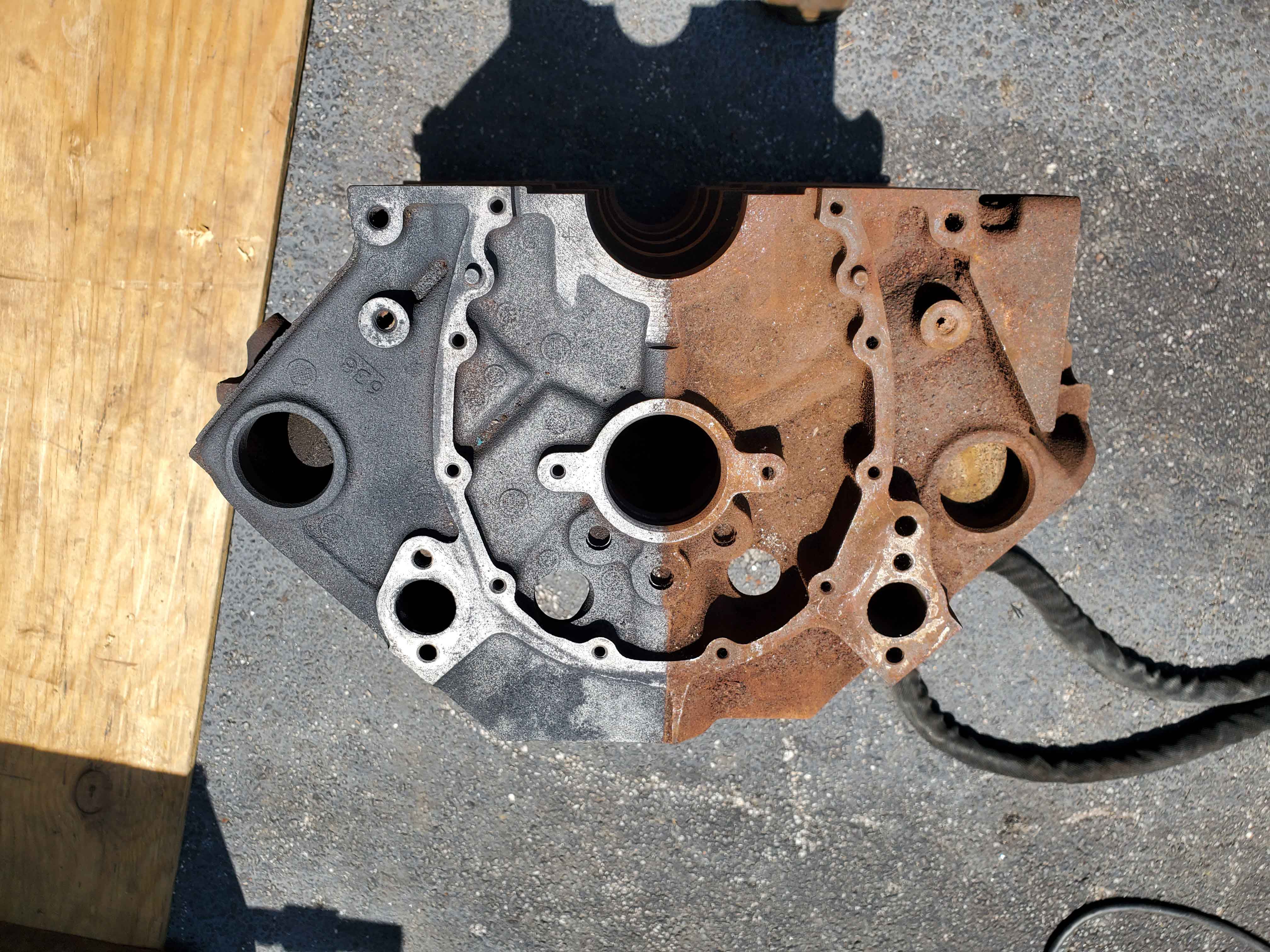

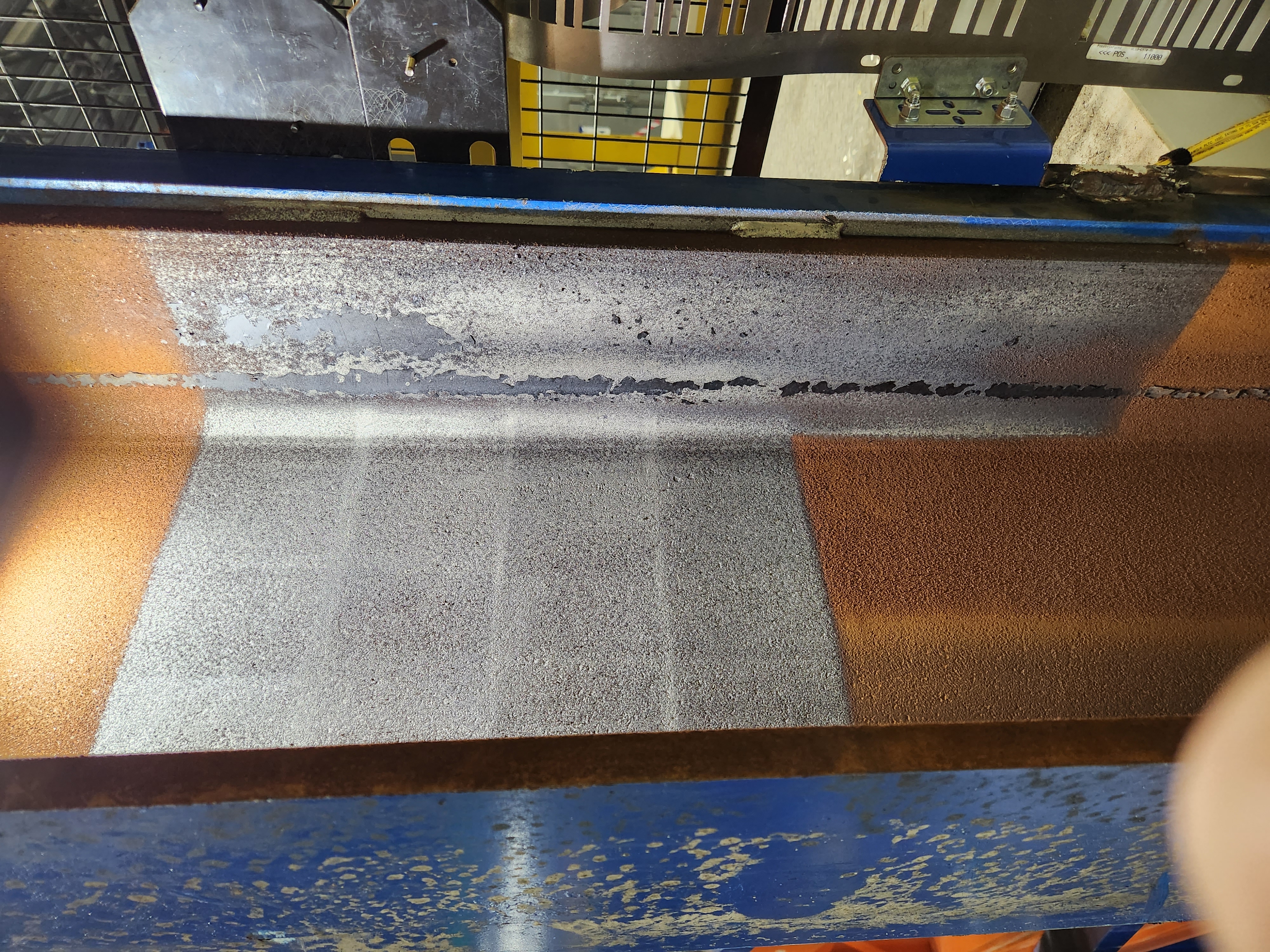

Southeast Laser Ablation Services provides laser cleaning services for projects large and small. Southeast Laser leverages state-of-the-art laser technology to clean surfaces without compromising substrates and base materials. Unlike other solutions, laser cleaning technology is quick to set up, can be implemented without loss of productivity or equipment downtime and is safe for the environment.

Services Include:

- NDT/NDI surface preparation

- Injection mold cleaning

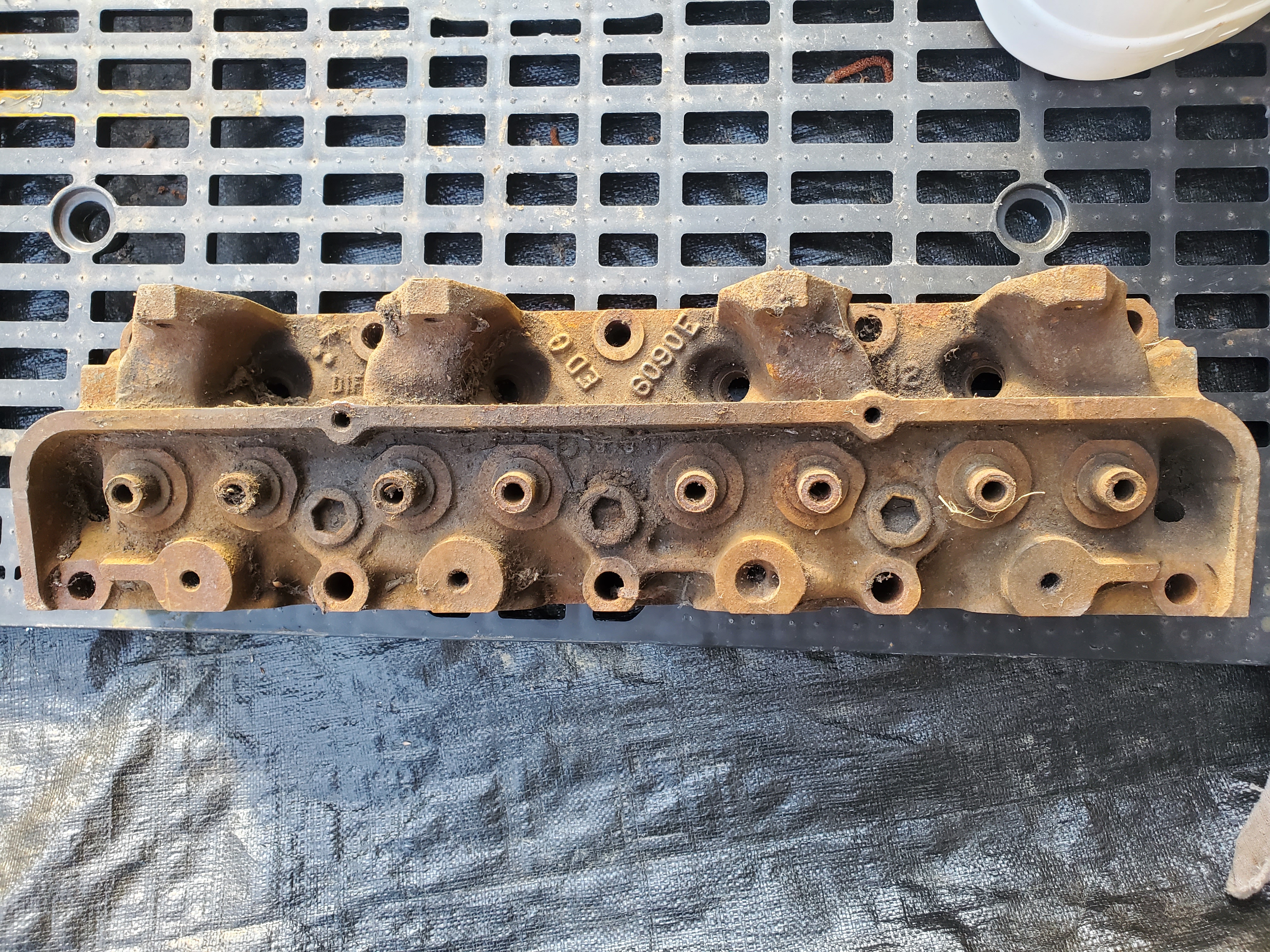

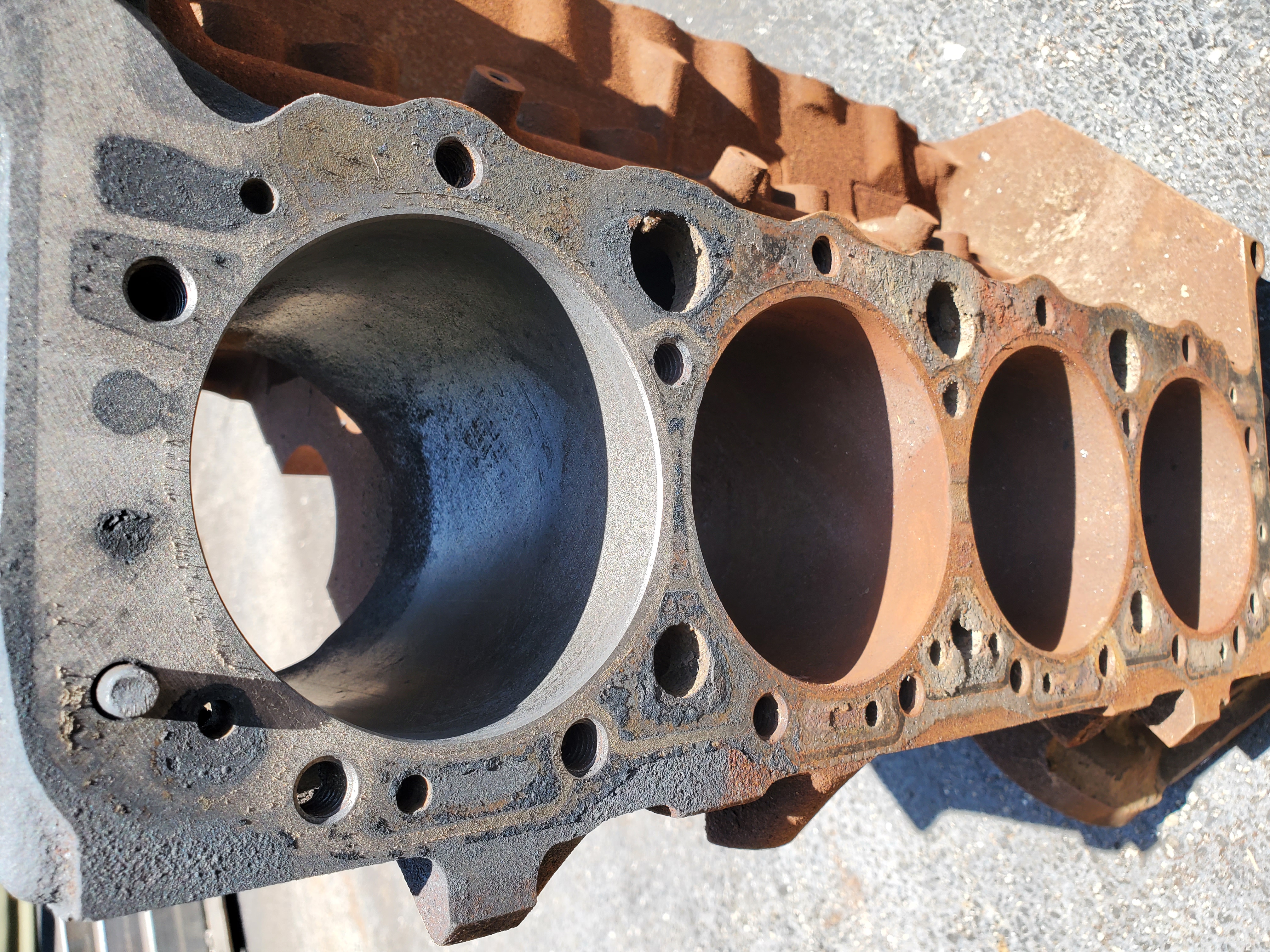

- Corrosion cleaning

- Oxidation/rust removal

- Coating removal

- Paint removal

- Adhesive bond/coating preparation

- Oil removal

- Surface structuring

- Stone, brick and concrete restoration

- Chemical removal

- Welding/Bonding treatments

- Vibratory Services

Industries

Industries are increasingly looking to laser ablation not only for the precision and efficiency they provide, but also for the low waste generated. Low waste and high efficiency provide environmentally friendly surface cleaning and maintenance that traditional solutions can't produce.

- Manufacturing

- Aerospace

- Automotive

- Military & Defense

- Nuclear

- Oil & Gas

- Polymers

- Sanitation

- Sanitation

- Utilities

- Disaster Remediation

- Painting

- Mining

- Antiques

- Restoration

- Collision Repair

Environmentally Friendly

Laser cleaning is considered the greenest, most environmentally-friendly way to remove particulates from surfaces because it requires no chemicals or solvents, doesn't waste water and doesn't require costly preparation or extensive cleanup.

This method uses a laser beam to vaporize material quickly and efficiently remove particultes with no risk to the technicians. Laser ablation is quickly becoming the industry standard. Quick. Safe. Cost effective.

Contact Us Today!

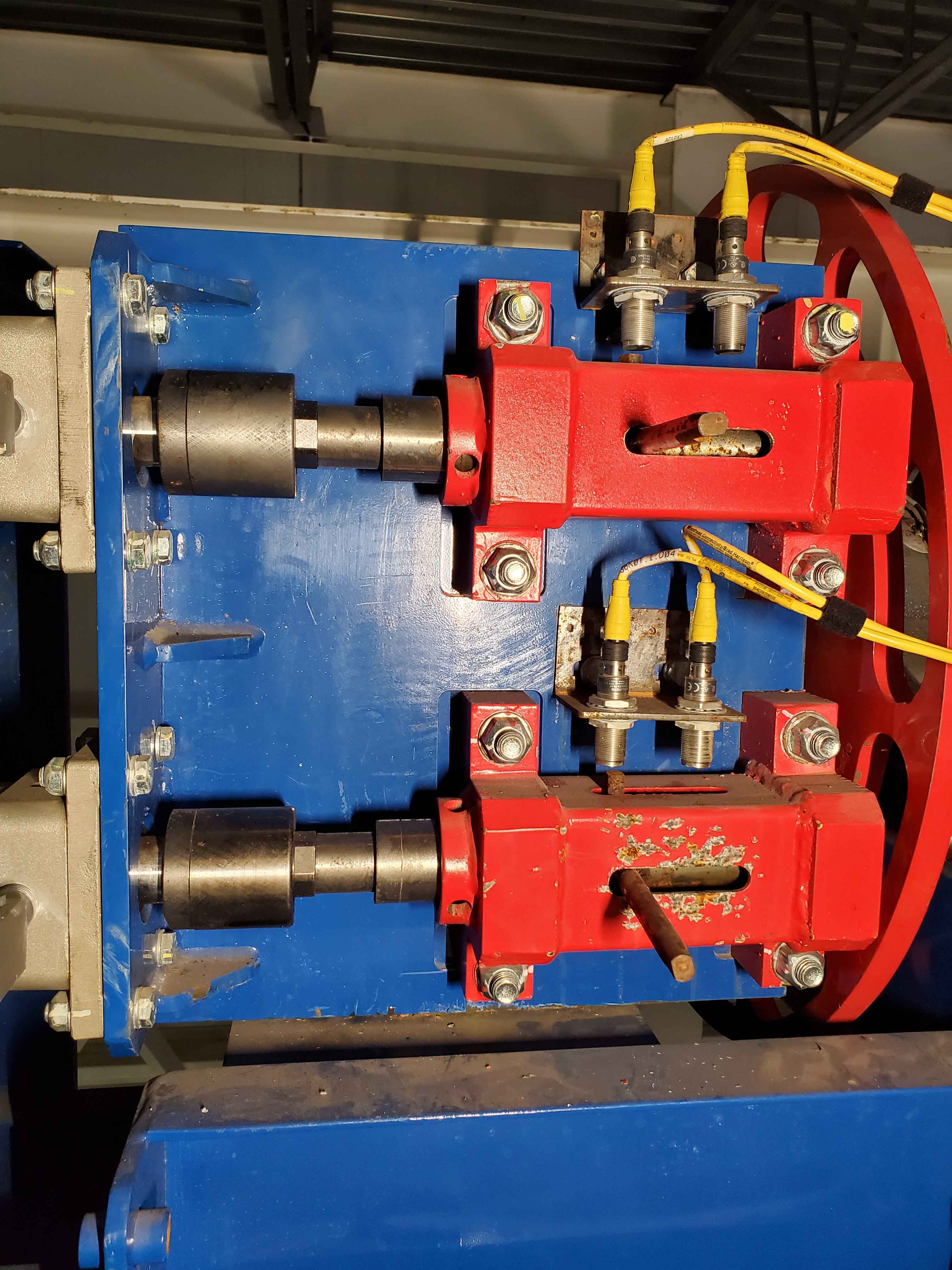

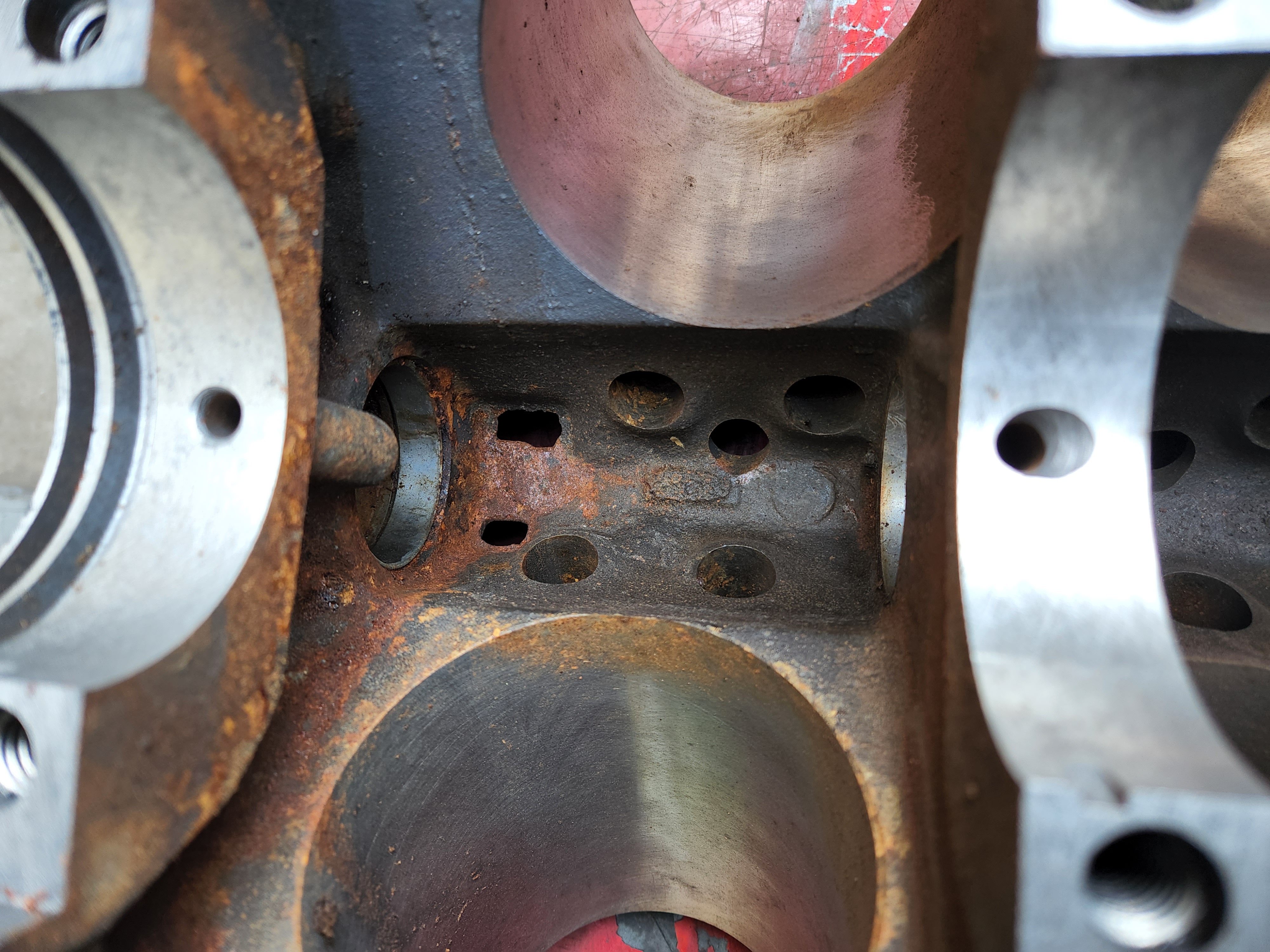

Vibratory Services

Vibratory Services

What Is Vibratory Cleaning/Polishing?

Vibratory finishing is a manufacturing process that deburrs, descales, burnishes, cleans, and brightens to smooth, consistent finishes for multiple parts and products. The process can be completed quickly and efficiently by allowing many products to be finished together without compromising the individual integrity of the individual piece. Specially shaped pellets of media are placed into a vibratory tumbler and can be operated either as a "wet" or "dry" solution depending on the application.

Vibratory finishing machines are especially good at meeting strict requirements and specifications, due to the nature of the relationship between the media and the substrate.